0

+ sets of machines now running in our users' factories around the world.

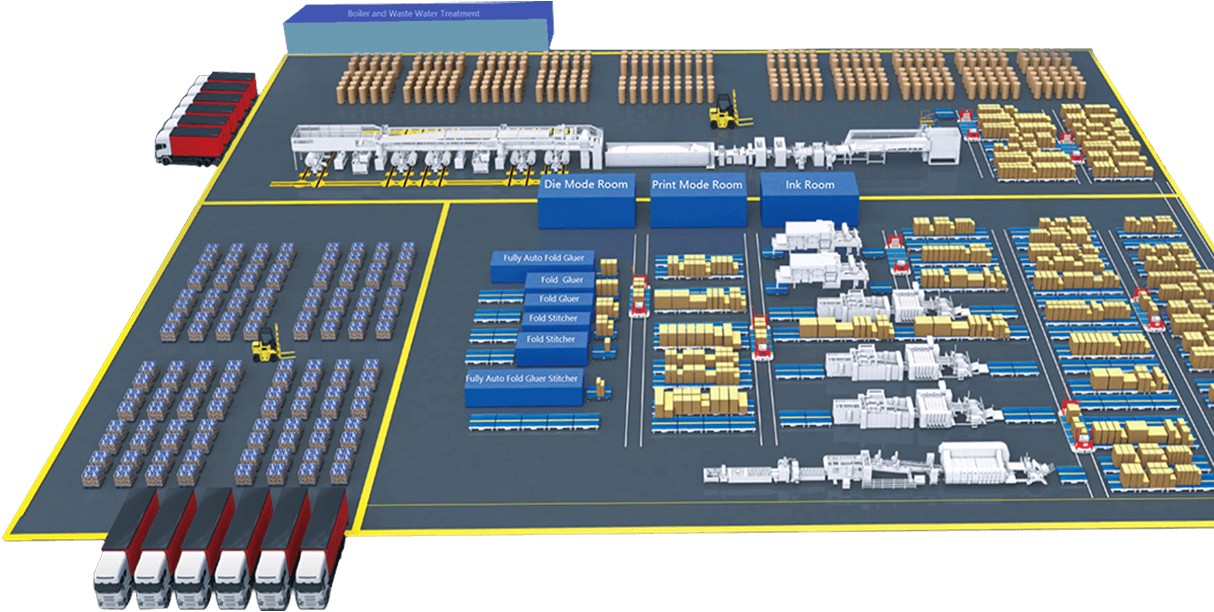

Global China Boxing Package Machinery Group – is Group company controlled by K & L, it is a globalization supplier of paperboard carton box manufacturing equipment, corrugated cardboard, corrugated box printing, die-cutting, fold gluing stitching equipment. Manufacturing complete sets of paper package mechanical engineering, factory engineering, logistics engineering and intelligent digital solutions. It can be customized to meet the complex requirements of various carton and corrugated box packaging markets, and finally realize the turnkey project. With China's incredible packaging development history. We have a clear and long-term development vision for the future of the world. We are long-term partners of customers in the intelligent era. We embrace change and innovation. Our values remain unchanged because we are rooted in the continuous development of the global economy. Committed to providing our users in the global market with high-quality services and achieving win-win sustainable cooperation and development. Although we come from China, the technology, products, sales and good reputation services of Global China Boxing Package Machinery Group have now spread all over the world. Our global network helps to provide every customer faster consulting, engineering planning & design and remote online services in the 5G era. Group Companies' History: KL & Japan Shinko One of the leading enterprises in China's carton printing industry, acquired the century old Japanese enterprise of corrugated printing machine(Shinko Machine Mfg Co., Ltd.) in August 2017. Provides Shinko Fully servo control high-speed automatic printing slotting die-cutting machine (1-6 colors), Fully auto Inline printing slotting die-cutting fold gluing enjector, "6 + 1" high-precision printing slotting die-cutting machine, Integrated Top and Button printing slotting die-cutting machine, Jumbo fully auto printing slotting die-cutting machine, rotary die cutting and other products. ISO9001 certification, and was selected as a specialized new "little giant" enterprise by China Ministry of industry in 2021. Osaka plant in Japan continues to be the R & D and production base of K & L. Now the largest production base is in Guangzhou, China. The main spare parts are imported from Japan, and experienced Japanese technicians keep working in Guangzhou factory to guide, install and check the machine on site, so as to ensure that the quality of the machine meets the same standards of Japan plant! WEST RIVER In 1978, the creator of China's first semi-auto corrugated cardboard production line, and participated in the formulation of national manufacturing standards for China's corrugated industry. provides a series of 2ply single face to 3Ply, 5Ply, 7ply Corrugated cardboard production lines and customized design solution, width from 1200mm-2800mm, and speed ranges 150-350m/min. Started from 1954 as the China Navy mechanical parts manufacturing factory in Zhaoqing City, it has rich experience in mechanical manufacturing. Takes the corrugated cardboard production line equipment as the leading factor in the group to implement the complete service aiming at the turnkey project of the whole plant equipment design solution. NANTAI Nantai cooperates with Japan world famous enterprise (ASAHI MACHINERY LIMITED) to manufacture the world's leading Asahi series AP-2100, AP-165E, AP-1600, AP-1700, AP-1060 fully auto Flat Bed Die Cutter and ASM-1700 Paper cutting machine in Foshan City, China. In 1995, it was awarded the Sasaki award by Japan TAPPI. And to realize the development of CARTONMASTER, it develops GLUEMASTER serires to realize the continuous production of automatic die-cutting and gluing carton and hardboard box. At the same time, it has established production and service bases in South Korea and Europe. GUANWEI A scientific and technological lead enterprise focusing on the high-end whole plant logistics for packaging plant, integrating R & D, manufacturing, sales and service, providing whole plant layout planning services, 3D warehouse, paper roll conveying, cardboard conveying, finished product conveying and high-end spare parts with automatic control intelligent technology and ERP full plant control. Advocate the development concept of high-end intelligent transportation equipment and provide customers with intelligent solutions for the whole plant's intelligent logistics transportation. It can provide customized design, manufacturing and after-sales service for enterprises according to different situations and actual needs of users. JIAYI China's leading Carton box Fully Auto Fold Gluing Machine, Fully Auto Fold Stitching machine and the R&D, production and manufacturing base. With deep professional knowledge and rich experience in carton box folding, gluing, stitching. With the advanced production technology integration of Europe, the United States, ...

More About

Contact Us

Heavy Duty 7Ply Corrugated Cardboard Production Line

Heavy Duty 7Ply Corrugated Cardboard Production Line

K7io Bottom Printing Slotting Die-cutting Machine

K7io Bottom Printing Slotting Die-cutting Machine

Flexo High Speed Printing Slotting Die-cutting and Inline Machine

Flexo High Speed Printing Slotting Die-cutting and Inline Machine

Automatic Flatbed Die-cutter AP-2100

Automatic Flatbed Die-cutter AP-2100

Automatic folder inline gluer and stitcher

Automatic folder inline gluer and stitcher

Automatic folder gluer JW B-Type

Automatic folder gluer JW B-Type

Automatic corrugated cardboard conveyer system

Automatic corrugated cardboard conveyer system