※ For small size products, high-speed cutting can be carried out by installing 2 knives

※ Multi roll cutting at the same time (optional, up to 10 layers)

※ The paper feeding section and the paper receiving section are equipped with multiple paper tappers to make the paper receiving more orderly

※ Reduce the weight of rotor, reduce the consumption of motor = save power

Brand:

WEST RIVERGoods Stock:

1Product Origin:

ChinaColor:

CustomizedShipping Port:

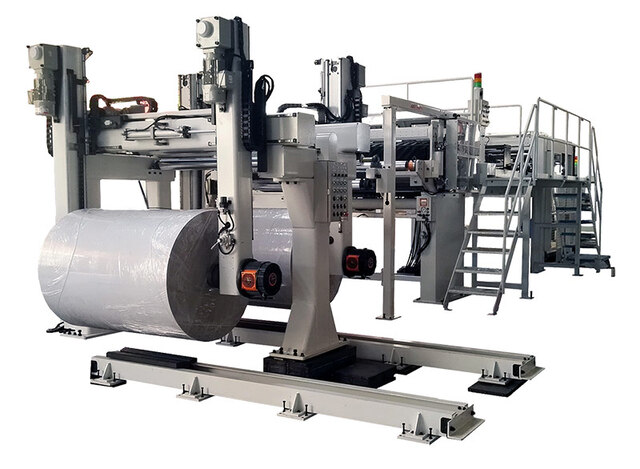

Shenzhen/GuangzhouHigh Speed Paper Cutting Separation Machine

※ The change of various sizes can be changed instantaneously

※ Simple and convenient blade replacement operation

※ Smooth and flat cut over other cutting devices

※ Reduce a lot of waste

※ Reduce the process of edge grinding and print directly to the printing machine

| Model | ASM-1700 |

| Paper type | general paper jam |

| Paper weight | 127-500g / m2 |

| Roll size | width 1600mm (maximum), diameter 1200mm (maximum) |

| Number of paper of run | usually 2, can be multiple (optional, up to 10) |

| Cutting length | 450-1350mm |

| Paper width | maximum 1600mm |

| Running speed | maximum 200m / min (could be changed by the length of paper cutting) |

| Paper cutting accuracy | + / - 0.15mm or less (Zero run out of cutter shaft) |

| Tension control | According to the web diameter control (open circuit mode), Disc brake, Tension 50-110kg / full |

| Paper splitting knife | roller double knife, short single double knife available |

| Paper cutting device | push type synchronous paper cutting (2 knives) |

| Power | 380V / 50Hz |

| Air pressure | 5kg / cm2, use dehumidified air |

| Setting place | first floor |

Features:

Product Show

FAQs

1Q: Are you the manufacturer?

A: Yes, we are the professional manufacturer combined with WEST RIVER, KL&Japan Shinko, Nantai & Japan Asahi, Jiayi, Guanwei, Jinshun brand machines.

2Q: Where are your factory located in ?

A: Our factories located in Shanghai, Guangzhou, Foshan, Zhaoqing Cities in China

3Q: How to choose the corrugated machine ?

A: According to your market requirement for the cardboard thickness, your target requirement, raw material size, we will give you the best choice of the corrugated machine.

4Q: What can you do for me?

A: Usually the customer need to choose the corrugated machine, flexo printer, die cutter and other converter machine separately by different supplier, but we will give you the whole plan design solution from A to Z, what you need to do is just tell us your target, then you will get the most suitable proposal from us.

5Q: How to control machine quality ?

A: All material are environmental protection,non-pollution, We have professional technicists to supervising to production, Our professional department to examine about every production process

6Q:What can you do if the machine face problem?

A: We provide the machine remote service system, and the warranty period is 1 year. If the broken parts can't repair, we can send the new parts to replace the broken parts for free, but you need to pay the freight. After warranty period, we will charge for the maintanance, and we supply the technical support for the whole life of the equipment.

Tags :