Shinko Super Alpha full servo control 5 layer corrugated carton production line.

Brand:

KL & Japan ShinkoProduct Origin:

CHINAColor:

CUSTOMIZEDShipping Port:

YANTIAN/SHEKOU PORTShinko Japan High Speed Corrugated Carton Flexo Printing Machine Features:

1. One-button operation function(test printing with one sheet, regular production can be done.)

2. Equipped with remote diagnosis and maintenance function.

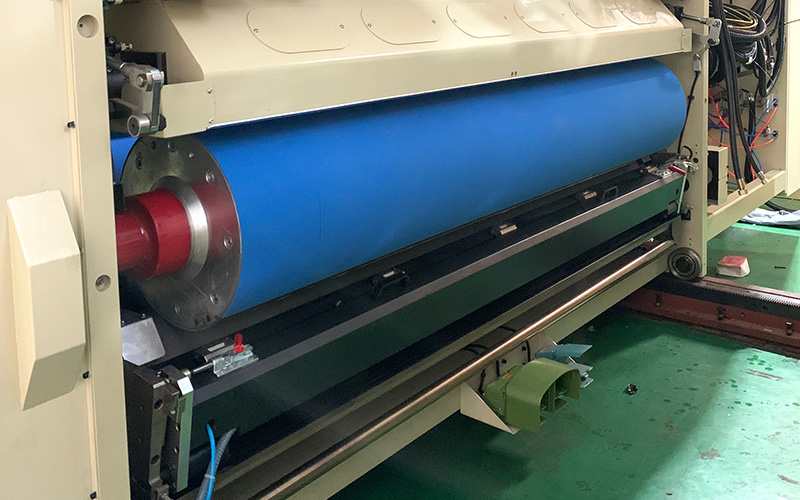

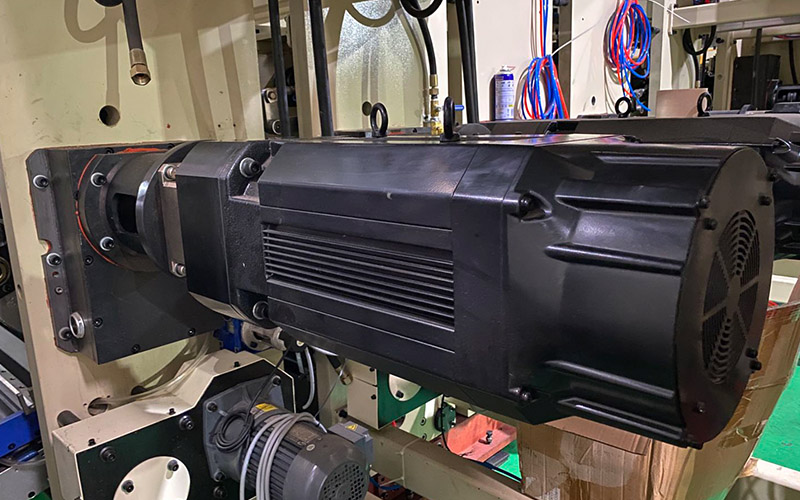

3. Full servo-driven feeding unit, printing unit, slotting unit, die cutting unit.

4. Adopt Japan Yaskawa servo control system.

5. The printing cylinder is driven by a servo motor, and it takes only 15 seconds to rotate a circle.

6. Adopts computerized automatic plate-locking system.

7. Dual slotting unit(creasing unit+slotting unit).

8. The whole machine is designed and manufactured according to high requirements, high speed, reliability and safety, quick order change and easy operation.

9. Able to connect to the ERP production management system.

Printer Slotter Die Cutter Machine Model size:

900x2000, 900x2400, 1200x2400, 1200x2800, 1400x2400, 1400x2800, 1600x2800, 1600x3200

Printing and Packaging Machine Max machine speed: 180~350 pcs/min.

Tags :