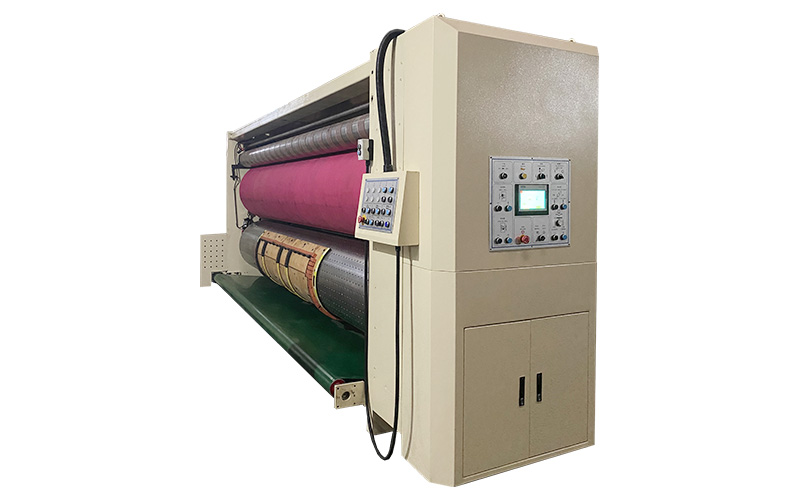

Automatic flexo ink printing machine, making for large size home appliance carton box.

Brand:

KL & Japan ShinkoProduct Origin:

CHINAColor:

CUSTOMIZEDShipping Port:

YANTIAN/SHEKOU PORTFlexo Top Printing Machine Features:

1. One-button operation function(test printing with one sheet, regular production can be done.)

2. Equipped with remote diagnosis and maintenance function.

3. This machine is designed and made to high quality and safety standard, with the advantages of high speed, auto control and quick shift.

4. Adopt high quality material and parts. All electronic components conform to CE standard, and safety standard can equal European.

5. Well hardened and ground transmission gear, hardness>60 HRC.

6. Auto zero return and auto reset.

7. Use expansion sets tight link to reduce abrasion of the shaft, keep precision of the machine for longer time.

8. All cylinders and rollers are chromed plated for ideal hardness.

9. PLC control system with touch screen control.

10.Able to save orders, speed up the order shift.

11.Able to connect to the ERP production management system(optional).

Rigid Box Making Model size:

1600x3600, 2200x3600, 2200x4000, 2200x4500, 2200x5300, 2600x3600, 2600x4000, 2600x4500, 2600x5300.

Box Carton Macinery Max machine speed: 80~120 pcs/min.

Customized for special thickness of sheet.

Tags :