Brand:

WEST RIVERGoods Stock:

1Product Origin:

ChinaColor:

CustomizedShipping Port:

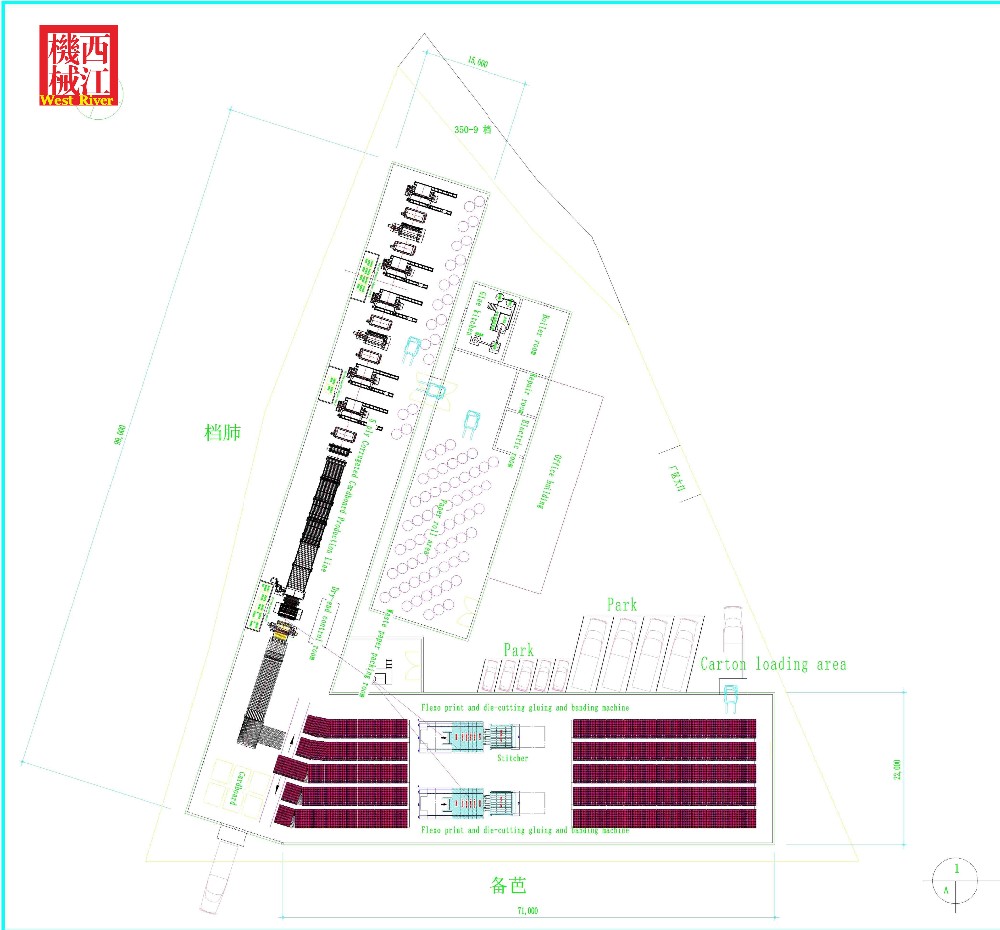

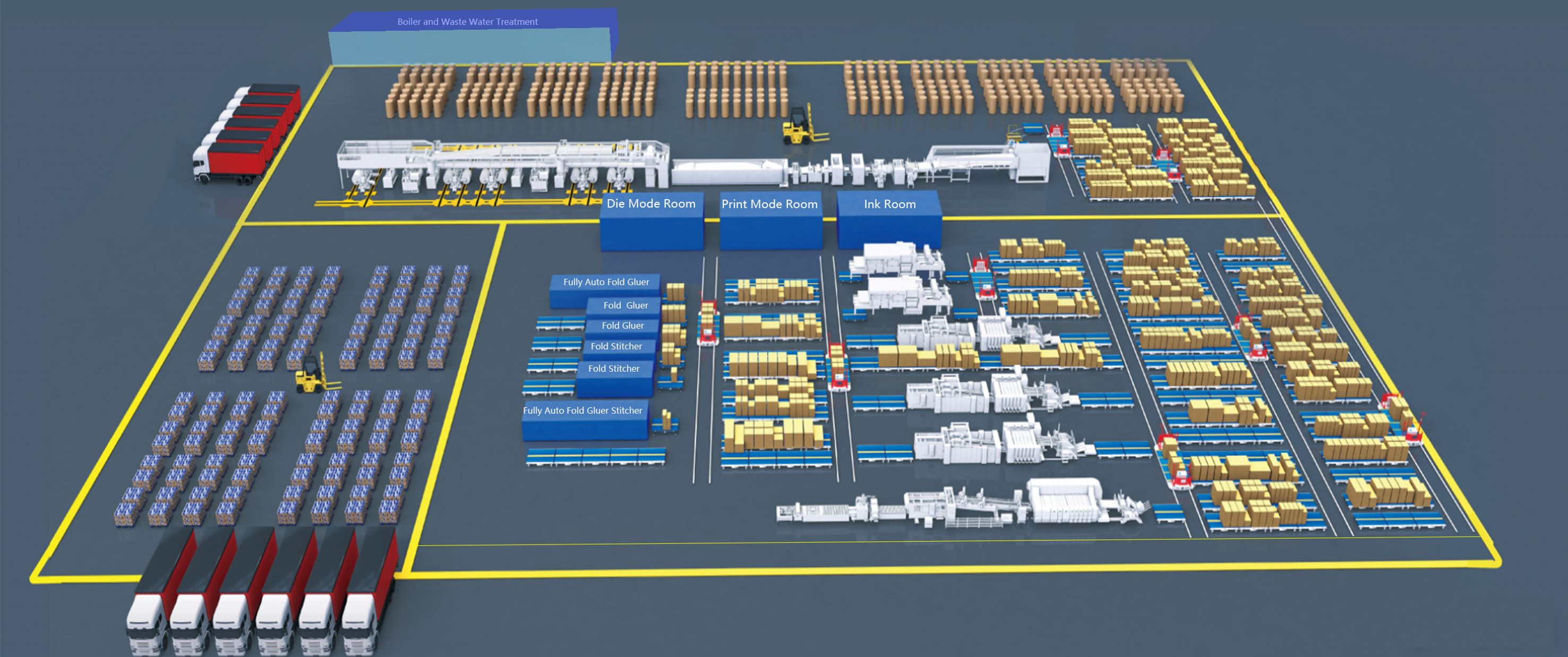

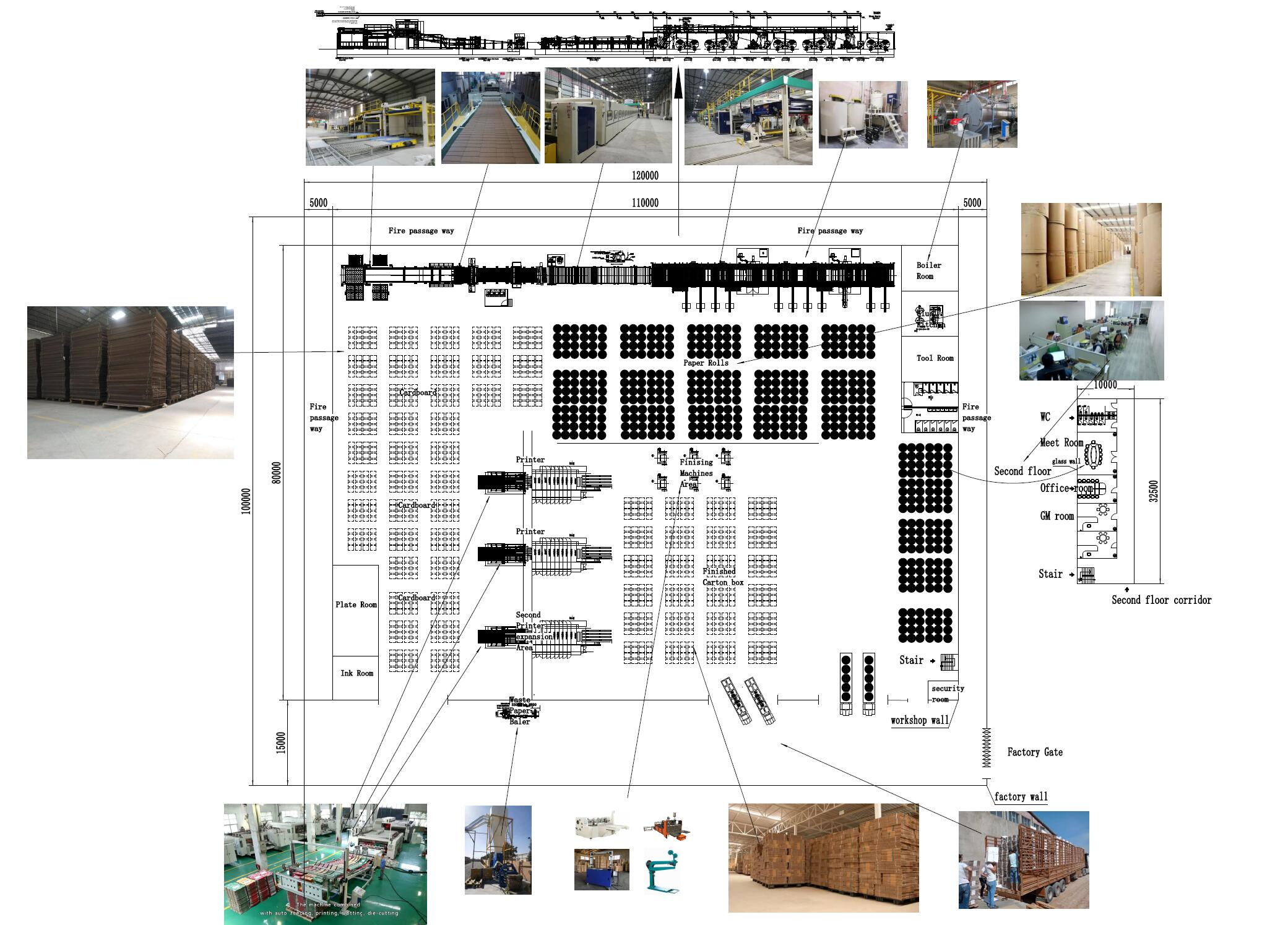

Shenzhen/GuangzhouFully automatic corrugated cardboard carton box making factory design

Complete corrugated cardboard carton box making factory from A to Z

Cardboard thickness: 3Ply 5Ply 7Ply

Width: 1200-2500mm

Speed: 120-350meters/min

Printing: 4,5,6 flexo high grapic printing

Including all the supporting equipment such as compressor, glue machine, boiler, baler...

Free of charge full carton factory layout design

high quality cardboard production

Features:

Production Capacity up to 1,000,000 sqm(1200mm orders) per day

Customized design solution according to customer requirements

Fully automatic 1200-2800mm Corrugated Machine

Fully automatic Shinko flexo printer, Asahi Die Cutter, fold gluer, waste baler...

Provides factory built guidance and layout design

Provides manufacturing, installation, testing and operation training.

Realize Turnkey project design

Product Show

FAQs

1Q: Are you the manufacturer?

A: Yes, we are the professional manufacturer combined with WEST RIVER, KL&Japan Shinko, Nantai & Japan Asahi, Jiayi, Guanwei, Jinshun brand machines.

2Q: Where are your factory located in ?

A: Our factories located in Shanghai, Guangzhou, Foshan, Zhaoqing Cities in China

3Q: How to choose the corrugated machine ?

A: According to your market requirement for the cardboard thickness, your target requirement, raw material size, we will give you the best choice of the corrugated machine.

4Q: What can you do for me?

A: Usually the customer need to choose the corrugated machine, flexo printer, die cutter and other converter machine separately by different supplier, but we will give you the whole plan design solution from A to Z, what you need to do is just tell us your target, then you will get the most suitable proposal from us.

5Q: How to control machine quality ?

A: All material are environmental protection,non-pollution, We have professional technicists to supervising to production, Our professional department to examine about every production process

6Q:What can you do if the machine face problem?

A: We provide the machine remote service system, and the warranty period is 1 year. If the broken parts can't repair, we can send the new parts to replace the broken parts for free, but you need to pay the freight. After warranty period, we will charge for the maintanance, and we supply the technical support for the whole life of the equipment.

Tags :